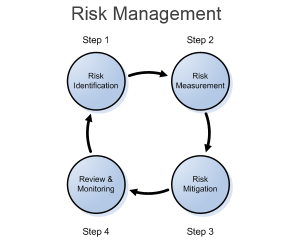

COVID-19 and the Risk Management Process

covid-19 and the risk management process

Risk Identification

Let’s start by considering how COVID-19 could impact our business operations. Obviously there are many ways COVID-19 could be transmitted, but we encourage everyone to begin to identify the potential hazards and interactions that increase chances throughout your operation. In fact, OSHA requires employers to assess hazards in which an employee may be exposed. The CDC also has a hazard identification assessment that may be helpful found here. Here are four common risk identification areas to start with:

1) Employee contracts the virus, and comes to work even though they aren’t feeling well.

2) Employee is asymptomatic and comes to work not knowing they are carrying the virus.

3) Employee interacts with customer, who is carrying the virus.

4) Virus is transferred from a surface area.

Risk Measurement

The likelihood and severity of COVID-19 impacting your business is not easily defined, but very important to study. You should have an idea of roughly how much revenue you’re generating per day and be able to calculate the consequence of an infection within your company.

In some states, like Colorado, there are mandatory shutdowns that are being required for businesses that have an infection outbreak. Per Colorado’s CDHPE’s Workplace Outbreak Guidance: preventing, reporting, and mitigating outbreaks are necessary if you experience the following:

One case of infection – the affected areas are to be closed for 72 hours and disinfected

Two cases of infection in 30 days – entire facility disinfected and closed of 72 hours.

Three cases in 30 days – entire facility disinfected and closed for 14 days.

Think about the impact these mandatory shutdowns could have and use these numbers to express to your employees how serious you are about safe workplace practices. Also, consider if you could lose jobs after notifying customers you aren’t able to operate due to a COVID-19 shutdown?

Risk Mitigation

Mitigating the risk comes with two trains of thoughts.

1. How to we prevent it from happening originally?

2. If it does happen, what do we do to control it?

Using an example of having two employees in the same truck driving to the jobsite, I’m sure you can come up with some pretty simple ways to mitigate the transmission of COVID-19. Many tree care companies have moved towards having employees drive their own vehicle to avoid multiple employees in one truck cab. Simple adjustments, similar to wearing a mask when within 6 feet of another employee, can make a huge difference in stopping the spread prior to an outbreak.

Masks can lower the risk of COVID-19 infection to you, your employees, and your customers. Masks and or face coverings used at the appropriate times in conjunction with proper hygiene and social distancing can greatly mitigate much of this risk. Research shows that people who have no symptoms can spread COVID-19, so wearing a non-medical face mask or face covering helps minimize the spread of the virus.

Your company should also have a response plan in place, detailing the actions necessary for limiting transmission if an employee does test positive for COVID-19. You’ll need to know who the employee has interacted with, which area they’ve been active in, and what equipment they’ve used at the very least. Note that other employees may have to quarantine as well if they’ve been in close contact, and again consider the impact that could have on your business.

Review and Monitoring

At this point, you’ve already done a lot of the leg work. Review the effectiveness of your program and make sure you update your response program as we learn more about the virus. Moving forward, you’ll be ready if there is another wave and will not have to rely on emergency measures for similar situations.

The ArboRisk team has been very active in helping tree services with proper risk management during this time. Reach out to ArboRisk today to get help directly or visit TCIA’s COVID-19 webpage for additional guidance on policy development that is provided specific to tree care Once developed communicate the policies to all that are exposed to these risks.

And remember, the risk management process can and should be used for more than just COVID-19!

Sources(Image):

https://www.comindwork.com/weekly/2018-10-29/productivity/risk-management-process

Written by: Malcolm Jeffris, CTSP

Recent Comments